emd locomotive

Forum Posts

-

Posted in the topic Diesel Locomotive Spares Manufacturer And Emd Turbocharger parts in the forum Introduce YourselfDecember 7, 2025 9:54 PM PST

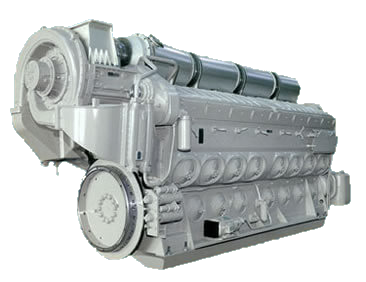

Introduction Of EMD Turbocharger Parts

Electro-Motive Diesel (EMD) locomotives are globally recognized for their high reliability, powerful engine output, and efficient turbocharging systems. https://asa-equipments.com/emd/","data-mce-href":"https://asa-equipments.com/emd/"}">ASA Engine Equipments supplies premium EMD Turbocharger Parts for EMD 645, 710, and older 567 series engines to customers across USA, Canada, Australia, Bangladesh, Germany, France, UK, Italy, Romania, Austria, Turkey, Mexico, Mozambique, Sri Lanka, Senegal, and Republic of Liana.

🔧 What is an EMD Turbocharger?

An EMD turbocharger is a high-performance air-boosting system designed to increase engine efficiency by delivering higher air pressure for combustion. It improves power output, reduces emissions, and ensures stable operation under heavy load.

Turbocharger increases air density

Enhances fuel burn efficiency

Improves locomotive pulling performance

Reduces black smoke and fuel wastage

The turbo system is a critical part of all EMD 645 & 710 engines, used worldwide for freight, passenger, and marine operations.

https://asa-equipments.com/","data-mce-href":"https://asa-equipments.com/"}"> src="https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhjhMvKeHprVUJ5B-BMBAf0zBZeN4MlHgvcaIMYYaeI6fFmcvvsOnBC2b_z4f9gVhAYpFCggOznNjAC4-cPlWrNtYEVdcbp_NbseAvbzvPKwUBIMS8bMpYIo2zzK3GuVF5gz70J9GpIIwoc9P-43qxM76q7U7L1UHJ6qF2cnbioRhpTjZFz_sW_v2FRQiI/s320/EMD.png" alt="" width="320" height="247" border="0" data-original-attrs="{"data-mce-src":"https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhjhMvKeHprVUJ5B-BMBAf0zBZeN4MlHgvcaIMYYaeI6fFmcvvsOnBC2b_z4f9gVhAYpFCggOznNjAC4-cPlWrNtYEVdcbp_NbseAvbzvPKwUBIMS8bMpYIo2zzK3GuVF5gz70J9GpIIwoc9P-43qxM76q7U7L1UHJ6qF2cnbioRhpTjZFz_sW_v2FRQiI/s320/EMD.png"}" data-original-height="282" data-original-width="366">

🔩 Major EMD Turbocharger Parts We Supply

Below are major turbo components with full descriptions:

- Turbocharger Rotor Assembly

The rotor is the heart of the turbocharger, responsible for converting exhaust gas energy into rotational speed. Our rotors are manufactured using high-grade heat-resistant alloys to withstand extreme operational temperatures.

Details:

Precision-balanced for smooth rotation

Provides stable boost pressure

Reduces vibration and turbo lag

Compatible with EMD 645 & 710 models

- Turbo Compressor Wheel (Impeller)

The compressor wheel delivers compressed air to the intake manifold. ASA supplies CNC-machined impellers for maximum airflow and efficiency.

Expanded Explanation:

Lightweight design ensures faster spool-up

Resistant to deformation under heat

Enhances horsepower and torque

Supports continuous high-speed rotations

- Turbocharger Diffuser

A diffuser helps stabilize airflow and pressure. We supply steel and alloy diffusers for all major turbocharger versions.

Benefits:

Smooth transition of compressed air

Reduces pressure shock inside the turbo

Maintains consistent air delivery

- Nozzle Ring Assembly

Nozzle rings direct exhaust gas flow towards the turbine wheel. Our rings are engineered for optimal heat endurance.

Key Features:

Provides uniform gas distribution

Increases turbine efficiency

Minimizes energy loss

- Turbo Journal Bearings

Journal bearings stabilize the rotor and reduce friction. Our bearings are made from high-strength bronze alloys.

Details:

Enhances rotor life

Supports high-RPM performance

Reduces wear & operational noise

- Turbocharger Blower Housing

The blower housing encloses the turbocharger components. Made from strong cast iron, it ensures structural safety.

Benefits:

High thermal resistance

Prevents external damage

Maintains optimal airflow paths

- EMD Turbocharger Oil Pump

The turbo oil pump ensures lubrication for bearings and moving components.

Important Points:

Reduces friction

Prevents overheating

Increases turbo lifespan

🚂 EMD Turbocharger Compatibility

Engine Model Turbocharger Type Interchangeable Parts EMD 645 Turbocharged Rotor, diffuser, impeller, rings EMD 710 High-boost turbo Rotor, bearings, oil pump EMD 567 Legacy turbo Select compatible components 🧪 Technical Specifications

Component Material Temperature Tolerance Lifespan Rotor Nickel-alloy 900°C+ Long life Impeller Forged Aluminium 650°C High RPM resistance Journal Bearings Bronze Alloy 450°C Extended life Diffuser Steel Alloy 750°C Strong airflow stability 🛠 Installation Tips for https://asa-equipments.com/emd-locomotive-spare-parts-europe/","data-mce-href":"https://asa-equipments.com/emd-locomotive-spare-parts-europe/"}">EMD Turbocharger Parts

- Verify Rotor and Bearing Alignment

Misalignment can cause vibration and premature wear. Manual rotation should feel smooth without resistance.

- Ensure Proper Lubrication Before Starting

Dry turbo starts are the #1 cause of failure. Always pre-lubricate.

- Check for Air Leakages

Loose clamps or cracked pipes reduce boost pressure and engine power.

- Follow OEM Torque Specifications

Over-tightening or loose tightening affects performance and safety.

🧰 Maintenance Tips for Long Turbocharger Life

- Maintain Clean Oil System

Dirty oil damages bearings. Replace oil regularly.

- Monitor Boost Pressure Levels

Sudden drop = leak or damaged rotor

Sudden rise = blockage or over-boost

- Prevent Overheating

Allow engine to idle before shutdown to cool the turbo.

- Regular Inspection of Blades

Bent or chipped blades reduce airflow efficiency.

❗ Common Turbocharger Problems & Solutions

Problem 1: Excessive Smoke

Cause: Weak turbo pressure

Solution: Check for leaks or rotor damage

Problem 2: High Fuel Consumption

Cause: Low air boost

Solution: Inspect diffuser and impeller

Problem 3: Loud Whining Noise

Cause: Bearing failure

Solution: Replace journal bearings immediately

Problem 4: Low Engine Power

Cause: Wastegate stuck or air blockage

Solution: Clean and inspect air pathways

🌍 Countries We Supply https://asa-equipments.com/emd-locomotive-spare-parts-europe/","data-mce-href":"https://asa-equipments.com/emd-locomotive-spare-parts-europe/"}">EMD Turbocharger Parts To

We export globally to:

USA, Canada, Australia, Bangladesh, Germany, France, UK, Italy, Romania, Austria, Turkey, Mexico, Mozambique, Sri Lanka, Senegal, Republic of Liana.

“We supply EMD Turbocharger Parts to the USA, Canada, and Australia for freight and passenger rail.”

“Our EMD 645 and 710 turbo components are widely used in Germany, France, UK, Italy, and Romania.”

“ASA Engine Equipments exports EMD turbo parts to Bangladesh, Sri Lanka, Mozambique, and Republic of Liana.”

❓ FAQs

Q1: Are these turbocharger parts OEM quality?

Yes, all parts meet OEM specifications and undergo strict quality testing.

Q2: Do you supply EMD 645 and 710 parts internationally?

Yes, we ship to 15+ countries worldwide.

Q3: What is the lifespan of an EMD turbo rotor?

With proper maintenance, 5–10 years under normal operating conditions.

Q4: Do you provide complete turbo kits?

Yes—complete assembly kits are available for 645 & 710 models.

Conclusion

https://asa-equipments.com/ge-locomotive-engine-parts-usa/","data-mce-href":"https://asa-equipments.com/ge-locomotive-engine-parts-usa/"}">EMD Turbocharger Parts are essential for locomotive performance, fuel efficiency, and engine reliability. With high-quality components, expert engineering, and global supply expertise, ASA Engine Equipments provides the best turbocharger solutions for the worldwide railway and marine sectors.

Recent Blog

https://asa-equipments.com/alco-locomotive-engine-parts/

https://asa-equipments.com/ge-locomotive-engine-parts-usa/

https://asa-equipments.com/emd-locomotive-spare-parts-europe/

https://asa-equipments.com/emd-turbocharger-parts/

https://asa-equipments.com/ge-locomotive-cylinder-head-usa/

https://asaengineequipments.blogspot.com/2025/12/emd-locomotive-spare-parts-supplier.html

https://asaengineequipments.blogspot.com/2025/12/ge-locomotive-engine-parts-types.html

https://asaengineequipments.blogspot.com/2025/12/emd-turbocharger-parts-global-supplier.html

https://asaengineequipments.blogspot.com/2025/12/ge-locomotive-cylinder-head-usa.html

https://ge-locomotive-engine-parts.jimdosite.com/

https://emd-turbocharger-parts-usa-canada.jimdosite.com/

https://in.pinterest.com/pin/1077697385842836180

https://in.pinterest.com/pin/1077697385842839148

https://in.pinterest.com/pin/1077697385842839192

https://tensor.art/projects/940550231601186660

https://sites.google.com/view/ge-locomotive-engine-parts-usa/home

https://sites.google.com/view/emd-locomotive-spare-parts-usa/home

https://latinverge.com/forums/topic/22959/emd-locomotive-spare-parts-for-567-645-710-engines/

This post was edited by emd locomotive at December 7, 2025 9:54 PM PST -

Posted in the topic EMD Locomotive Spare Parts for 567, 645 & 710 Engines in the forum News and AnnouncementsDecember 6, 2025 4:11 AM PST

EMD Locomotive Spare Parts

For 20+ years, https://asa-equipments.com/","data-mce-href":"https://asa-equipments.com/"}">ASA Engine Equipments has supplied EMD Locomotive Spare Parts to railway operators across the world. We specialize in OEM-grade and high-strength aftermarket components for EMD 567, EMD 645, and EMD 710 engines, the backbone of freight and passenger locomotives globally.

EMD (Electro-Motive Diesel) engines are known for reliability, efficiency, and unmatched performance in heavy-duty operations. This blog provides a complete breakdown of key spare parts, specifications, installation tips, maintenance guidelines, troubleshooting advice and international supply coverage.

EMD Locomotive Engine Models We Cover

✔ EMD 567 Series

One of the most famous two-stroke engines used worldwide. Known for rugged design and long-term reliability.

✔ EMD 645 Series

Enhanced version with better airflow, improved power output, and higher combustion efficiency.

✔ EMD 710 Series

A modern, high-horsepower engine used in demanding freight applications. Offers lower emissions and superior fuel economy.

Key EMD Locomotive Spare Parts

- EMD Power Assemblies

EMD power assemblies include the liner, piston, piston rings, connecting rod, and wrist pin. These assemblies are pre-balanced and designed for quick replacement. Our power assemblies provide stable performance under extremely high loads.

Explained

Power assemblies directly impact combustion performance and fuel efficiency. High-quality assemblies ensure stable compression, reduced wear, and minimized downtime. Using precision-machined components ensures long operational life and reliable engine behavior, even under extreme conditions.

- https://asa-equipments.com/ge-locomotive-engine-parts-usa/","data-mce-href":"https://asa-equipments.com/ge-locomotive-engine-parts-usa/"}">EMD Pistons & Piston Rings

Manufactured from high-grade forged steel, these pistons can handle high temperatures and crosshead loads. Our piston rings provide perfect sealing and compression.

Detailed lines:

The piston moves thousands of times per minute, so durability is critical. High-density steel prevents cracking, deformation, and heat fatigue. Precise ring gaps ensure correct sealing, improving combustion and lowering oil consumption.

- EMD Engine Liners

Our hardened steel liners maintain accurate cylinder geometry over long periods. They resist wear, corrosion, and temperature fluctuations.

Explained:

The liner must withstand constant friction and high piston speed. High-quality liners reduce internal wear, preventing scoring and blow-by. This increases engine life and enhances combustion consistency across cylinders.

- EMD Turbocharger Parts

We supply rotor assemblies, blower wheels, diffusers, and bearing kits for EMD turbochargers compatible with 645 & 710 models.

Explained:

Turbochargers deliver pressurized air into the engine, increasing power output. Quality turbo components maintain stable airflow and prevent vibration and imbalance. This improves overall engine performance and reduces fuel consumption.

- EMD Crankshaft & Bearings

Precision-balanced crankshafts and high-strength bearing sets maintain perfect rotational motion and load handling.

Explained:

Crankshafts transfer piston movement into rotational force. Even small imbalances can damage the engine. High-quality bearings reduce friction, maintain smooth movement, and prevent premature failures.

Technical Specifications Table

Part Compatible Models Material Features

Power Assembly 567, 645, 710 Steel Alloy Pre-balanced, long life

Pistons 645, 710 Forged Steel High heat resistance

Liners 567, 645 Hardened Steel Wear-resistant

Turbocharger Parts 645, 710 Alloy/Steel High airflow stability

Crankshaft Bearings 567, 645, 710 Alloy Low friction, durable

Installation & Maintenance Tips

✔ Power Assemblies

Ensure the liner seat is clean, measure bore size, and torque fasteners as per EMD manual.

✔ Pistons & Rings

Check ring end gaps and apply lubrication before installation.

✔ Turbochargers

Always inspect shaft play and oil supply lines to prevent overheating.

✔ Bearings

Monitor temperature and vibration to detect early wear.

Troubleshooting Guide

Issue Reason Solution

Low power Turbo failure Replace rotor/impeller

High oil consumption Worn rings Install new ring set

Overheating Clogged liner ports Clean cooling passages

Countries We Supply EMD Parts To

USA, Canada, Australia, Germany, France, UK, Republic of Liana, Bangladesh, Italy, Mexico, Sri Lanka, Turkey, Romania, Austria, Mozambique, Senegal.

"We supply EMD Locomotive Spare Parts to USA, Canada & Australia for high-demand freight operations."

"Our EMD 567, 645, and 710 engine components are exported to Germany, France & UK with reliable shipping support."

"ASA Engine Equipments provides EMD parts to Bangladesh, Sri Lanka, Mozambique & Republic of Liana for global locomotive fleets."

FAQs

Q1: Which EMD engines do your parts support?

A1: 567, 645 & 710 engines across freight and passenger locomotives.

Q2: Are these parts OEM-grade?

A2: Yes, all parts meet OEM specifications.

Q3: Do you export worldwide?

A3: Yes, to 15+ countries including USA, Canada, Australia & Germany.

Conclusion

https://asa-equipments.com/","data-mce-href":"https://asa-equipments.com/"}">ASA Engine Equipments delivers premium-grade EMD Locomotive Spare Parts for 567, 645 & 710 engines with global export support. Our components ensure durability, high performance, and reliable operation for railway fleets worldwide.

Recent Blog

https://asa-equipments.com/alco-locomotive-engine-parts/

https://asa-equipments.com/ge-locomotive-engine-parts-usa/

https://asa-equipments.com/emd-locomotive-spare-parts-europe/

https://asa-equipments.com/emd-turbocharger-parts/

https://asa-equipments.com/ge-locomotive-cylinder-head-usa/

https://asaengineequipments.blogspot.com/2025/12/emd-locomotive-spare-parts-supplier.html

https://asaengineequipments.blogspot.com/2025/12/ge-locomotive-engine-parts-types.html

https://asaengineequipments.blogspot.com/2025/12/emd-turbocharger-parts-global-supplier.html

https://asaengineequipments.blogspot.com/2025/12/ge-locomotive-cylinder-head-usa.html

https://ge-locomotive-engine-parts.jimdosite.com/

https://emd-turbocharger-parts-usa-canada.jimdosite.com/

https://in.pinterest.com/pin/1077697385842836180

https://in.pinterest.com/pin/1077697385842839148

https://in.pinterest.com/pin/1077697385842839192

https://tensor.art/projects/940550231601186660

https://sites.google.com/view/ge-locomotive-engine-parts-usa/home

https://sites.google.com/view/emd-locomotive-spare-parts-usa/home

This post was edited by emd locomotive at December 6, 2025 4:11 AM PST